METALCELL® Laquered – PP

PP is a sandwich panel with a cosmetic finish, made using a panel without finish such as the RAWCELL® Metal FP to which a painted aluminium skin (finish) is applied in place of one of the two structural raw aluminium skins. Main fields of application: construction, furniture, lifts, shipbuilding, railway, road.

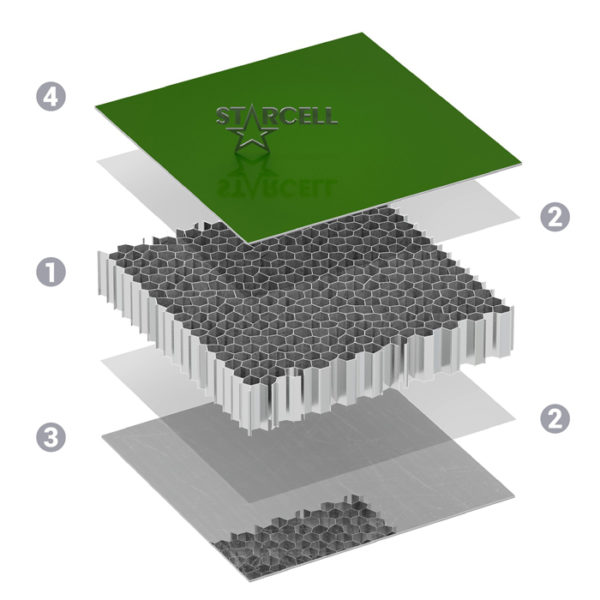

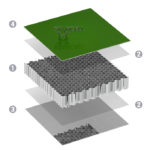

Layers

1) INTERNAL CORE

aluminium honeycomb

(Starcell production)

aluminium alloy: 3000-5000 series

density: 29 – 40 – 56 – 65 – 80 kg/m³

cell diameter:

10 mm (standard);

6.35 – 12.7 – 19 mm (on request)

2) ADHESIVE

thermoplastic/epoxy/polyurethane

3) EXTERNAL BACK SKIN

raw or primed aluminium sheet

skin thickness: 0.1 – 0.3 – 0.5 – 0.8 – 1.0 – 1.5 mm

other thicknesses on request

4) EXTERNAL FRONT SKIN (FINISH)

painted aluminium sheet

skin thickness:

0.1 – 0.3 – 0.5 – 0.8 – 1.0 – 1.5 mm

other thicknesses on request

Technical sheet of the panel

| PRODUCT ID CODE | ||||||||

| Code structure | Value in this sheet | Meaning | ||||||

| METALCELL® | family to which the product belongs | |||||||

| Laquered | subfamily to which the product belongs | |||||||

| PP (n/n)(n-n) | panel type | |||||||

| PP (n/ )( ) | 6,35/ = | size (mm) of the hexagonal honeycomb cell | ||||||

| PP ( /n)( ) | /n = | panel thickness (mm) | ||||||

| PP ( / )(n-n) | 1,0 - 1,0 | thickness (mm) of the two skins | ||||||

| S(n) | 8 = | standard dimensions (mm) - S(8) = 1.250 X 3.050 | ||||||

| CHARACTERISTICS OF MATERIALS AND COMPONENTS | ||||||||

| Front finishing layer | ||||||||

| material: | aluminium sheet | |||||||

| type: | painted | |||||||

| standard thicknesses (mm): | 0,1 - 0,3 - 0,5 - 0,8 - 1,0 - 1,5 | |||||||

| Structural skins | ||||||||

| standard thicknesses (mm): | 0,8 | |||||||

| standard adhesive: | thermoplastic - epoxy - polyurethane | |||||||

| Hexagonal cell honeycomb | ||||||||

| material: | aluminium foil | |||||||

| type: | alloy series 3000 - 5000 | |||||||

| foil thicknesses (µm): | 50 - 60 - 70 | |||||||

| density (kg/m³): | 29 - 40 - 56 - 65 - 80 | |||||||

| standard cell sizes (mm): | 10 | |||||||

| on request cell size (mm): | 6,35 - 12,7 - 19 | |||||||

| Back structural skin | ||||||||

| material: | aluminium sheet | |||||||

| type: | 1000 - 3000 - 5000 series alloy | |||||||

| standard thicknesses (mm): | 0,1 - 0,3 - 0,5 - 0,8 - 1,0 - 1,5 | |||||||

| surface appearance: | raw - primed | |||||||

| standard adhesive: | thermoplastic - epoxy - polyurethane | |||||||

| PHYSICAL AND DIMENSIONAL CHARACTERISTICS OF THE PANEL | ||||||||

| Dimensions | ||||||||

| standard (mm): | S(2) = 1.000 X 2.050 - S(7) = 1.250 X 2.550 - S(12) = 1.500 X 3.050 | |||||||

| special (mm): | maximum width: 1.500 - maximum length: 4.300 | |||||||

| tolerance (mm): | ± 1 (squared panels) | |||||||

| Thicknesses | ||||||||

| standard (mm): | 5 | 10 | 12,7 | 15 | 20 | 25 | 30 | |

| special (mm): | from 4 to 60 | |||||||

| tolerance (mm): | ± 0,3 | |||||||

| Weights* | ||||||||

| weights referred to standard thicknesses (kg/m²): | 3,29 | 3,32 | 3,43 | 3,56 | 3,83 | 4,10 | 4,37 | |

| tolerance (kg/m²): | ± 0,2 | |||||||

| *The weights refer to panels with the following characteristics: | cell size (mm): 10 | |||||||

| foil thickness (µm): 70 | ||||||||

| thickness of the skins (mm): 0,5 | ||||||||

| MECHANICAL CHARACTERISTICS OF THE PANEL | ||||||||

| The characteristics of this sheet refer to the following type of panel: | ||||||||

| METALCELL® Laquered - PP (6,35/n)(1,0-1,0)S(8) | ||||||||

| Starcell's Technical Department will gladly work with customers to determine the features of other panel configurations | ||||||||

| Type | Standard | Characteristic value | ||||||

| standard thicknesses | - | 5 | 10 | 12,7 | 15 | 20 | 25 | 30 |

| maximum load* (N): | DIN 53293; EN 14125 | 857 | ||||||

| deflection at Max* load (mm): | DIN 53293; EN 14125 | 3,49 | ||||||

| resistance to peeling* (N): | DIN 53295 | > 130 (min.) - >350 (average) | ||||||

| compressive strength* (Kg/cm²): | UNI 4913 | 26,4 | ||||||

| elasticity modulus (E)* (N/mm²): | DIN 53293 | 20.301 | ||||||

| stiffness modulus (R)* (N/m²): | DIN 53293 | 41 | ||||||

| thermal expansion coefficient* (°C⁻¹): | - | 2,3 x 10⁻⁵ | ||||||

| operating temperature (°C): | - | from -40 °C to +75 °C (on request +120 °C) | ||||||

| CERTIFICATIONS | ||||||||

| Type | Standard | Sector | Class | |||||

| fire behaviour of the panel | EN 13501-1 | CIVIL | A2-s1, d0 | |||||

| fire behaviour of the panel | IMO Res. MSC.307(88) - 2010FTP Code | SHIPBUILDING | C | |||||

| fire behaviour of the panel | UNI 11170-3 | RAIL | M1 F0 | |||||

| fire behaviour of the honeycomb | ISO 1182 | 0 | ||||||

| PROPERTIES | ||||||||

|

| FIELDS OF APPLICATION | ||||||||

| The METALCELL® Laquered - PP panel is widely used in the most diverse fields of application, thanks to its particular properties: moderate weight, high rigidity and flatness, excellent mechanical properties, fire resistance, no toxic fumes and dimensional stability over time. In the civil engineering field, it is chosen by architectural firms for its versatility both in the structural field (e.g. ventilated façades, floors, partition walls, sunshades, canopies, parapets) and in the finishing field (furnishings and fittings in general). In the transport sector, the railway and naval markets are two fundamental targets for using the panel, which is chosen to build partition walls, false ceilings, bathrooms and floors. The total recyclability of the panel, entirely made of aluminium, extends its use wherever regulations or commitment to environmental protection are an essential constraint. |

| STORAGE | ||||||||

| The METALCELL® Laquered - PP panel is a product in the “semi-finished products” category and therefore is subject to further processing; we recommend storing the panels horizontally in a closed and dry environment, possibly away from heat sources and to support them along their edges. |