RAWCELL® Metal

We produce panels with an aluminium honeycomb core, faced with raw sheet steel and aluminium skins, which are particularly robust and non-flammable

RAWCELL® Fiber

We offer a range of products with glass fibre skins impregnated with epoxy and phenolic resins, ideal for bonding marble, granite, glass and ceramic

RAWCELL® Wood

We offer panels with raw wood-based skins, easily workable and economical, designed for the furniture industry

HONEYCOMB PANELS WITHOUT FINISH

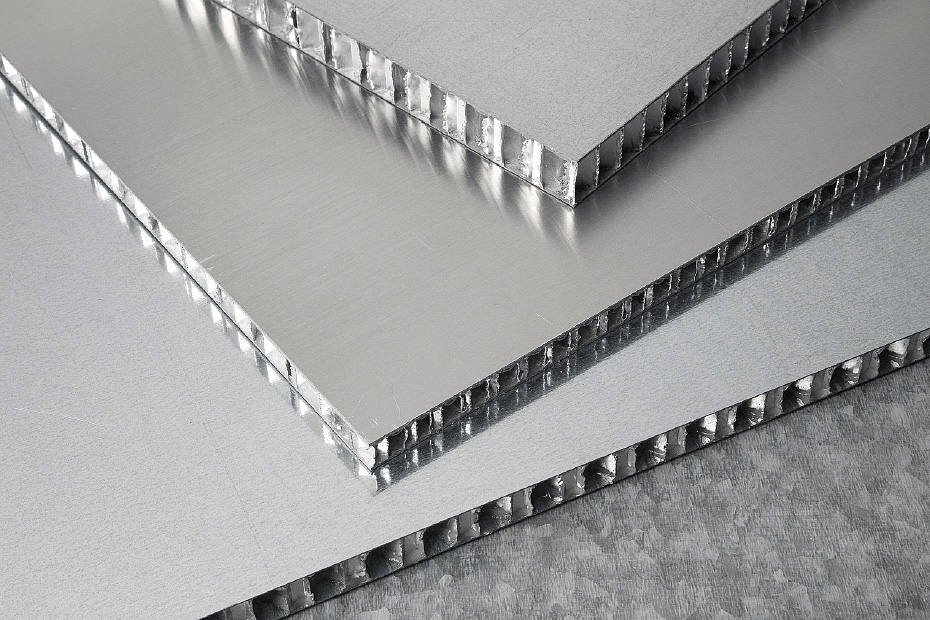

The typical structure of a composite panel consists of two parts: a particularly light inner element, called a core, and at least one pair of outer layers, commonly called skins, which closes the core on both sides. The core gives body to the panel, whereas the two outer skins perform an important structural function as they must withstand the main mechanical stresses. Composite panels without finish are products intended for subsequent processing by our customers, who buy the raw semi-finished product and deal independently with processing and finishing as needed.

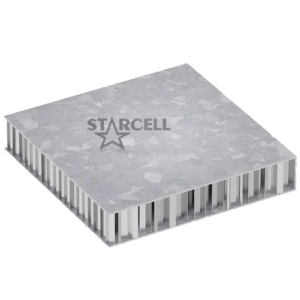

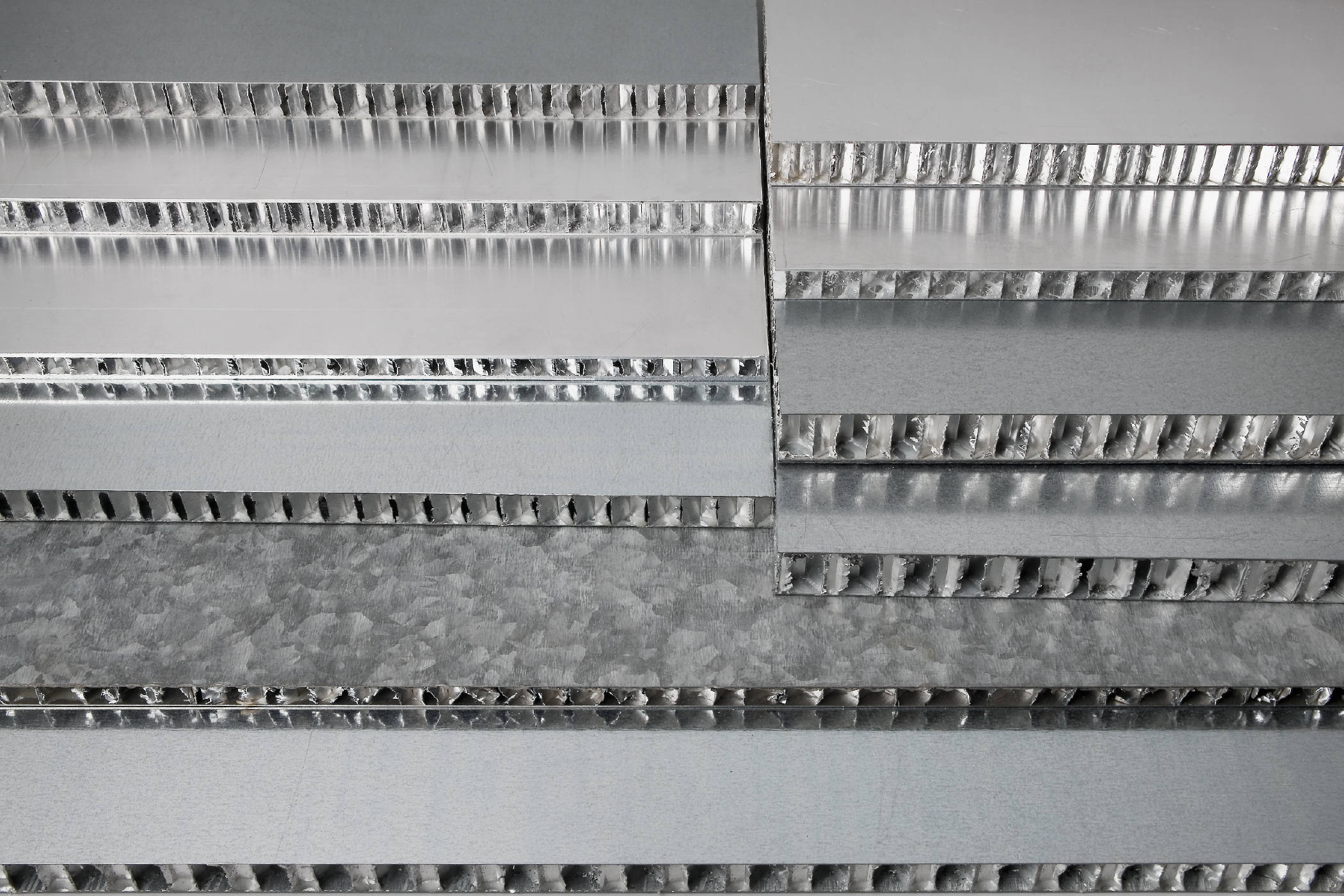

RAWCELL® METAL

The RAWCELL® Metal family includes a series of products without a cosmetic finish, featuring an internal aluminium honeycomb core and external skins made of various types of metal, in particular aluminium alloys and steel. The panels can be manufactured according to customer specifications, choosing not only the size/density of the cells, but also the thickness of the honeycomb core and that of the cladding skins.

The products included in the Rawcell® Metal family are used in almost all markets, since they are ideal wherever maximum performance is required in terms of mechanical resistance and fire resistance.

RAWCELL® Metal panels are used to build elevator cabins, ventilated walls, false ceilings, sunshades, raised floors, railway carriages, and ship and aircraft components.

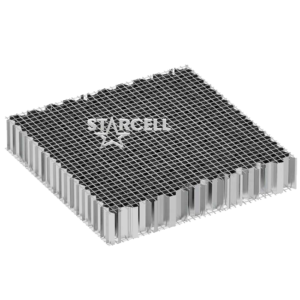

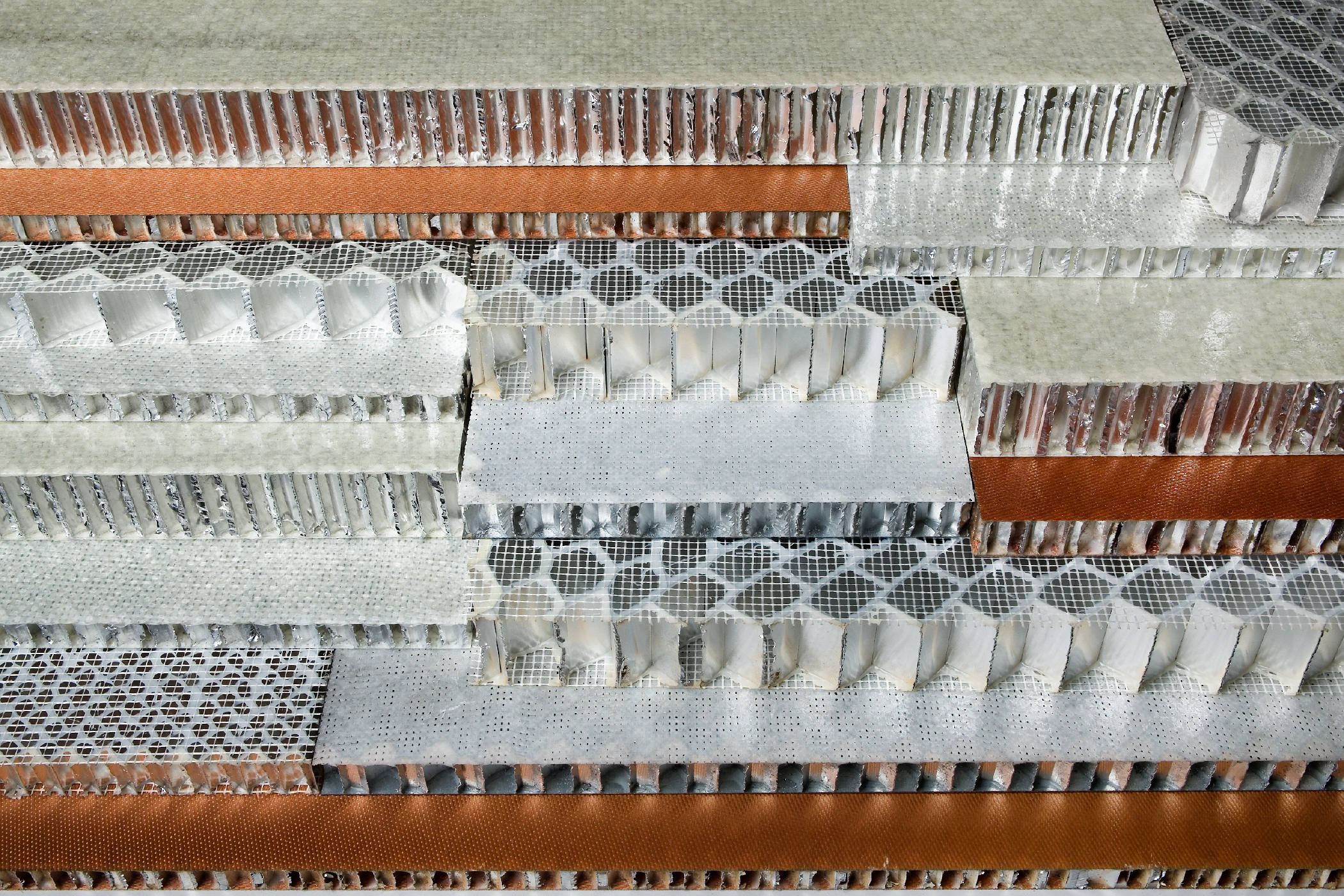

RAWCELL® FIBER

The RAWCELL® Fiber family is made up of panels without a cosmetic finish in which the aluminium honeycomb is covered with glass fibre skins impregnated with resins. Starcell has independently developed a series of fibre impregnation solutions in order to obtain skins with characteristics suitable for weight-reduction of materials such as marble and granite, but also glass, ceramic, reconstituted stone and mosaic.

The products included in the RAWCELL® Fiber family have been developed in order to optimise the behaviour of the panel in relation to the applicable finishing materials, as regards thermal expansion and to simplify certain types of processing, in situations where it is necessary to make cuts with machines which are not suitable for metalworking.

We can produce panels in many sizes, weights and thicknesses to meet any requirement.

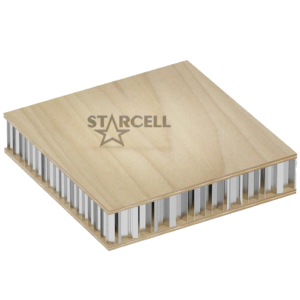

RAWCELL® WOOD

The RAWCELL® Wood family is made up of panels without a cosmetic finish that offer external wood-based skins in combination with internal aluminium honeycomb cores. Multi-layer (okoumé and poplar) and wood fibre (MDF) skins are available.

The products included in the RAWCELL® Wood family are used in the furniture industry. They are ideal for making partition walls, leaves and large doors and design items (tables, worktops, shelves and furniture in general). They can be finished with decorative laminates and many other materials. They are easy to process with any woodworking tool.

In addition to the standard formats and thicknesses, we can also develop customised solutions on a customer-specific basis.