Wall

cladding

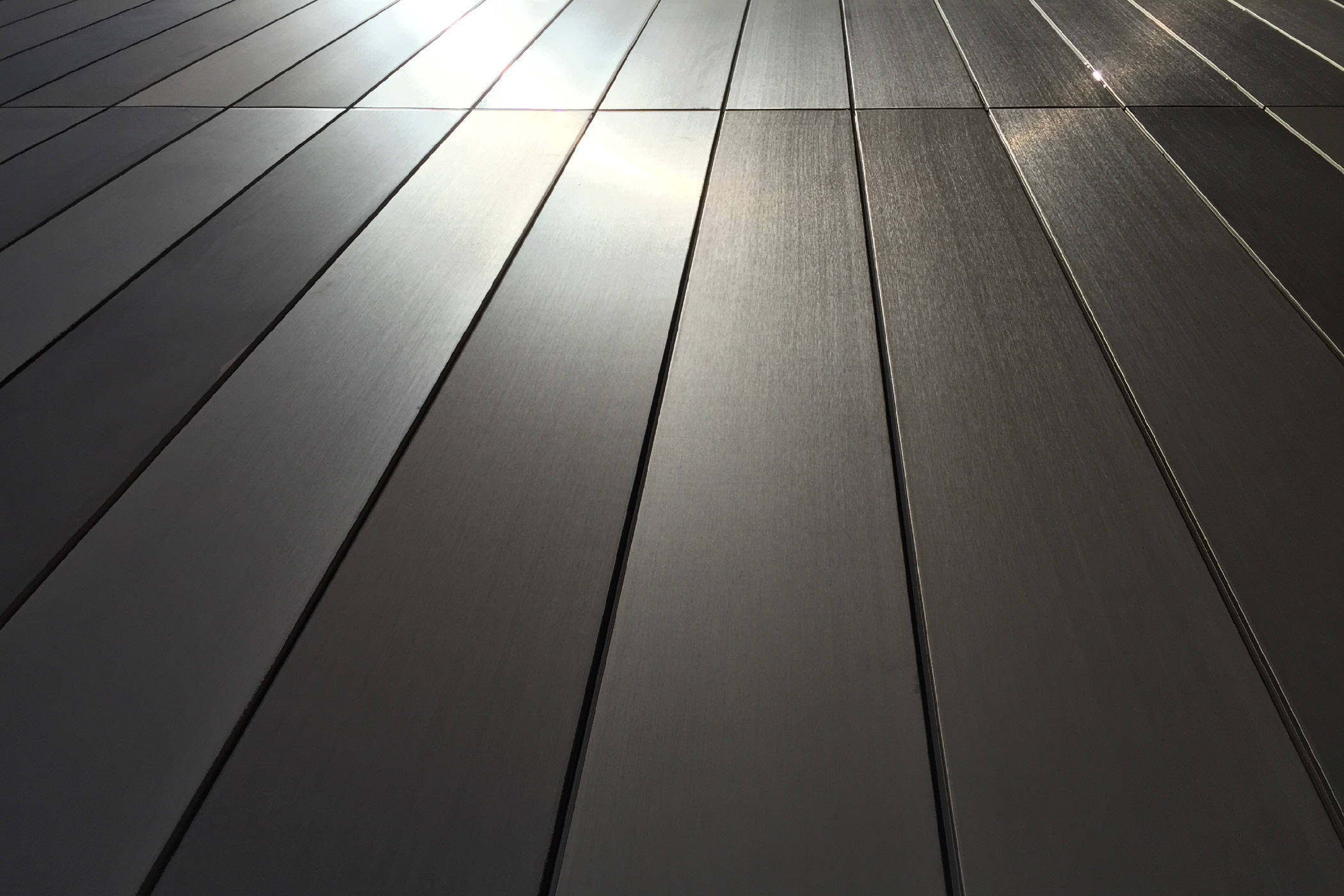

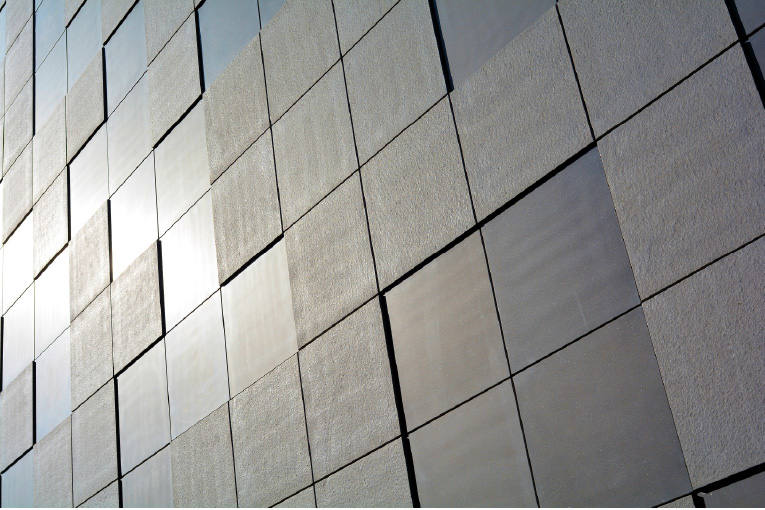

We supply panels covered with marble, granite, steel, aluminium and other materials to make ventilated façades

Raised

floors

We can make sturdy and light substructures, suitable for the construction of inspectable floors suitable for any premises

False

ceilings

Our panels are used in ceilings for large spaces: airports, hotel lobbies and wherever lightness, fire resistance and extra-large formats are required

Cladding of

large surfaces

When design and cosmetic quality are the project’s drivers, we certainly have a valid technical solution

CONSTRUCTION

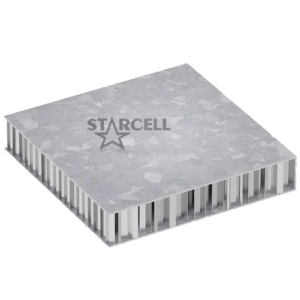

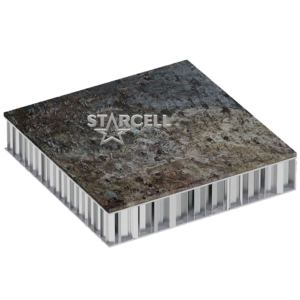

In the construction sector, Starcell composite panels are mainly used to cover vertical and horizontal surfaces and are widely used thanks to the advantages offered by this type of semi-finished product. The finishing materials traditionally used in construction are heavy or particularly rare and expensive or brittle. Combining these materials with a sandwich panel makes it possible to minimize the finishing layer, drastically reducing the weight and, often, significantly improving technical performance.

Contract

Civil engineering applications, in particular as area, have always been one of the most important markets for Starcell, both in terms of open-cell and solid core panels. Although the latter have lower mechanical performance than honeycomb, they are excellent for soundproofing and easy to install, besides being cost-effective and having a low cost of ownership.

Optimal solutions for this type of application are the panels with wooden skins of the RAWCELL® Wood family, which combine extreme lightness, ease of processing with normal manual or CNC equipment suitable for woodworking, low cost and robustness due to its internal honeycomb. If the fire resistance standards are more restrictive or the structural requirements are binding, it is possible to use panels with metallic skins from the RAWCELL® Metal family.

Ventilated façades

One of the most important applications in the construction sector is for the construction of ventilated façades. Starcell products can be used to build very large and lightweight cladding panels that are easy to handle and quick to install. Starcell has developed specific solutions for this type of application that take into account a range of special features such as the creation of watertight perimeter edges or the application of reinforcements on the rear side of the panel (RAWCELL® Fiber PGAL+LZ), necessary to ensure structurally safe fastenings and increase the life of the component, also improving its appearance.

Starcell can supply panels without a finish, leaving the finishing operations to third-party finishers with the materials chosen by the customer, but is able to provide complete solutions, thanks to its wide choice of panels with a finish. We can manufacture them according to customer specifications, both as to the type of finishing material applied, and the type of support. In addition, we can supply panels cut and machined to customer specs, according to tables and lists.

Raised floors

False ceilings

Composite panels with aluminium honeycomb cores become essential whenever large continuous surfaces are needed to hide channels and systems or where the design choices and the size of the module require uncommon solutions (large format, fine materials).

Starcell provides designers with its multifaceted experience in gluing as well as its sophisticated production systems to create couplings of innovative materials, to improve the environmental comfort and acoustic quality of spaces such as offices, industrial premises, concert halls, airport terminals, etc.