CONSTRUCTION OF HONEYCOMB PANELS

Producing a honeycomb panel is a complex process that involves several processing steps, many of which are fully automated.

1 – Aluminium

Coil

Honeycomb core production starts with aluminium alloy coils. The sheets are glued in layers and then cut into strips

2 – Honeycomb

expansion

The strips, cut to the desired height, are spread by means of special automated equipment

3 – Preparation

of sheets

The expanded sheets are prepared for gluing. The skins are applied on both sides to form the complete panel

4 – Panel

construction

The panels leave the production circle completely finished. The process ends with squaring that eliminates the irregularities of the edges, which are still present immediately after gluing

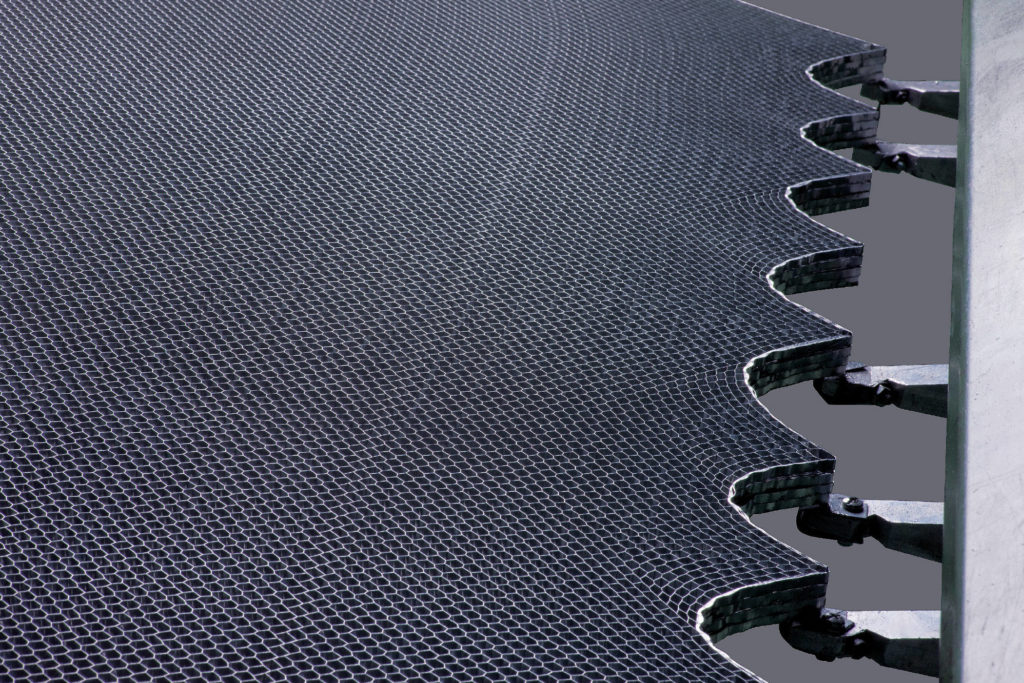

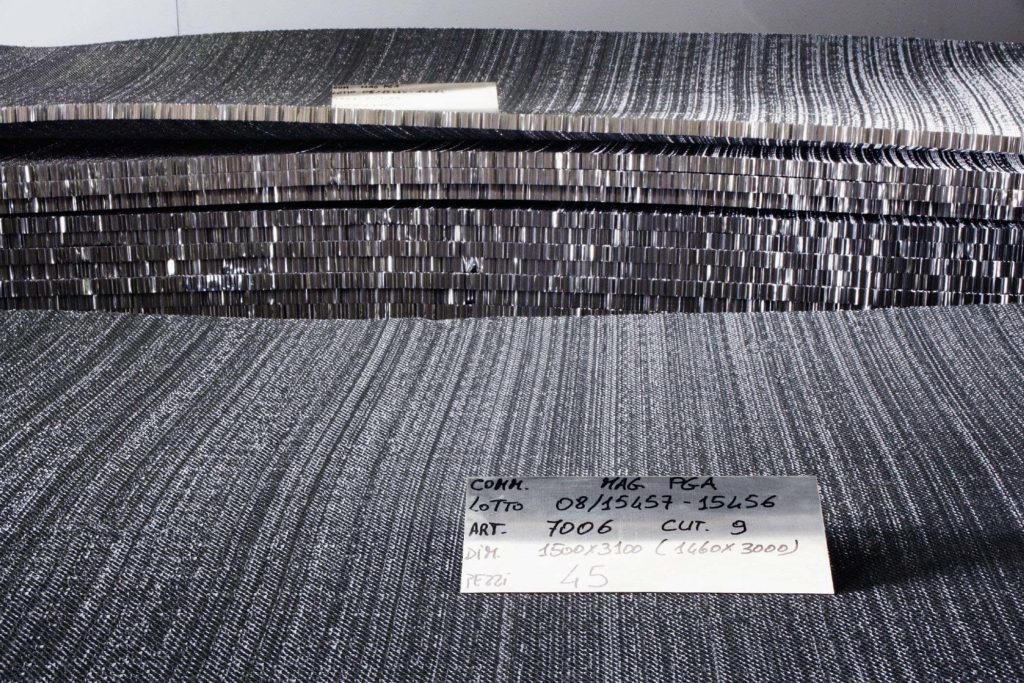

PRODUCTION OF THE HONEYCOMB CORE

Starcell S.p.A. manufactures aluminium honeycomb. We make aluminium alloy honeycomb using coils of 3000-series aluminium alloys.

To manufacture the semi-finished product we join aluminium sheets and, after gluing them, expand them using special machines to form the typical hexagon shape of the cells.

PRODUCTUION OF OPEN-CELL PANELS

Starcell® produces a wide range of sandwich panels, consisting of an inner core made of aluminium honeycomb and two or more outer skins made of various materials. The possibility of choosing both the thickness of the core and the density of the cells, as well as the type and thickness of the skins and the cosmetic finishes, make it possible to obtain an unlimited number of panel variants, each suitable to satisfy a particular requirement.

Starcell®’s remarkable production flexibility, combined with its propensity to tackle complex problems, according to specific customer requirements, makes it the ideal partner to identify and offer customised solutions.